Student Guide Sections

Introduction to Chemistry and Energy Efficiency

Insulation

Fertilizer and Crop Production

Lighting

Polymers

Lighting

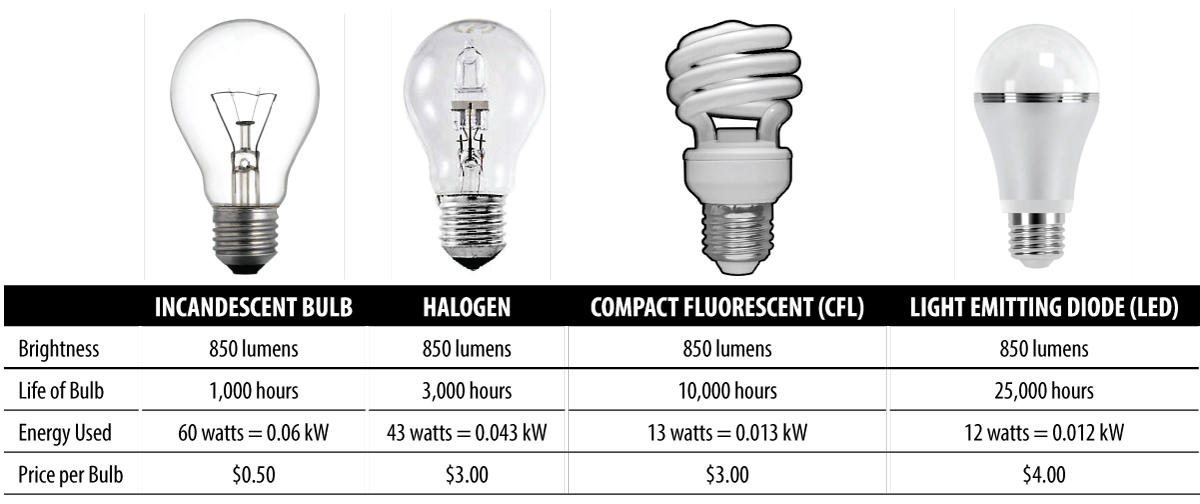

In the United States almost 40 percent of the electricity used by industry is for lighting. In homes around 13 percent of our electric bill is for lighting. As recently as five years ago, most of the light was produced by incandescent bulbs, using the same technology developed in 1879 by Thomas Edison. These bulbs are surprisingly inefficient, converting up to 90 percent of the electricity they consume into thermal energy rather than light. However, advances in technology have provided more efficient lighting options that more and more households are putting to use. These advances have changed the amount that households spend on lighting. In 2011, thirteen percent of electricity spending went toward lighting; now, only about five percent of billed electricity use is for light.

Compact fluorescent lights (CFLs) use up to 75 % less energy as incandescent bulbs and last up to ten times longer. Rather than running an electric current through a filament to make it glow, as in incandescent and halogen bulbs, an electric current travels through argon and a small amount of mercury. Ultraviolet light is produced – which then excites a fluorescent coating on the inside of the bulb. This produces visible light we can use. CFL bulbs fit almost any socket, produce a warm glow, and unlike the earlier models, no longer flicker and dim.Over the life of the bulbs, CFLs cost the average consumer less than one-third the cost of traditional incandescent bulbs for the same amount of light. In addition, CFLs produce very little thermal energy. The electrical energy going into the light bulb is primarily put to work producing light.

Compared to producing incandescent bulbs, manufacturing CFLs emits more carbon dioxide. However, when analyzing the entire life cycle of each type of bulb – manufacturing and use – CFLs have a lower carbon footprint. These savings come in the use phase of the life cycle. CFLs require much less energy to operate than incandescent bulbs. An incandescent bulb emitting 1550 lumens requires 100 watts of electricity while a CFL bulb only requires 23 watts. This means less electricity needs to be produced at the power plant to power the lights, which means fewer CO2 emissions from the power plant. Most incandescent bulbs are no longer being manufactured in the U.S.; however, specialty bulbs such as for appliances and 3-way bulbs are still available.

The McKinsey Report looked at global CFL usage. Around the world, nearly 3 billion CFL bulbs are manufactured annually. Taking into account that low quality CFLs have a reduced lifetime and efficiency, the analysis showed that over their lifetime, that amount of CFLs will prevent 700 MtCO2 from being emitted.

Once used mainly for exit signs and power on/off indicators, improved technology and lower prices are enabling light emitting diodes, LEDs, to be used in place of incandescents and CFLs.

The U.S. Environmental Protection Agency (EPA) and Department of Energy (DOE) have collaborated to form the Energy Star program, designed to help consumers save energy by choosing the most efficient products (http://www.energystar.gov/index.cfm?c=about.ab_index). To earn the Energy Star rating, LED bulbs must have a lifetime of 25,000 hours and use 75 to 80 percent less energy than comparable incandescent bulbs. The U.S. Department of Energy estimates that widespread adoption of LED lighting by 2027 would reduce electricity demand by 348 TWh, or the equivalent output of 44 large electric power plants. At today’s prices, $30 billion would be saved by wide usage of LED lighting.